A cheesy story about how Thin Client as an industrial PC reliably perform in tough manufacturing environments where traditional PCs fail

“Hey, Jerry. Here’s another failed PC we had to pull from the floor. Would you check it out to see if it’s repairable?” Like so many times over the past several years, Jerry was handed a non-functioning computer, pulled from the production floor of perhaps the most well-known boxed macaroni and cheese manufacturer in the U.S. Jerry almost knew what the problem was before he even examined the computer. The tell-tale clue was all over the computer’s case—orange powder. As he opened the case, he saw just what he had come to expect: a fan blade and motor choked with powdered cheese.

The computers in the mac & cheese production line were just like the computers used in an office environment. The problem was that the production line was not a clean office environment; powdered cheese was packaged and put into boxed macaroni and cheese kits to be sold in grocery stores. Despite the use of sophisticated production equipment and a regular cleaning regimen, an invisible cloud of orange, powdered cheese dust floated in the air and settled on every surface. The PCs in that area were cooled by fans that pulled external air in and across the processor and board components.

Just consider…At an average of 50 cfm, over a 12-hour day, a single PC pulls 36,000 cubic feet of air through the fan and over the circuitry. For a production line that’s trying to keep up with America’s mac & cheese demand by running 7 days per week, that’s over 13 million cubic feet of air filled with powdered cheese. Though the typical lifespan of a heavily used desktop PC is 3 years, powdered cheese dramatically shortens that.

The cost of computer replacements could easily be factored into the production expenses associated with making America’s most popular boxed mac & cheese, but what about the costs and operational disruptions from frequent computer failures?

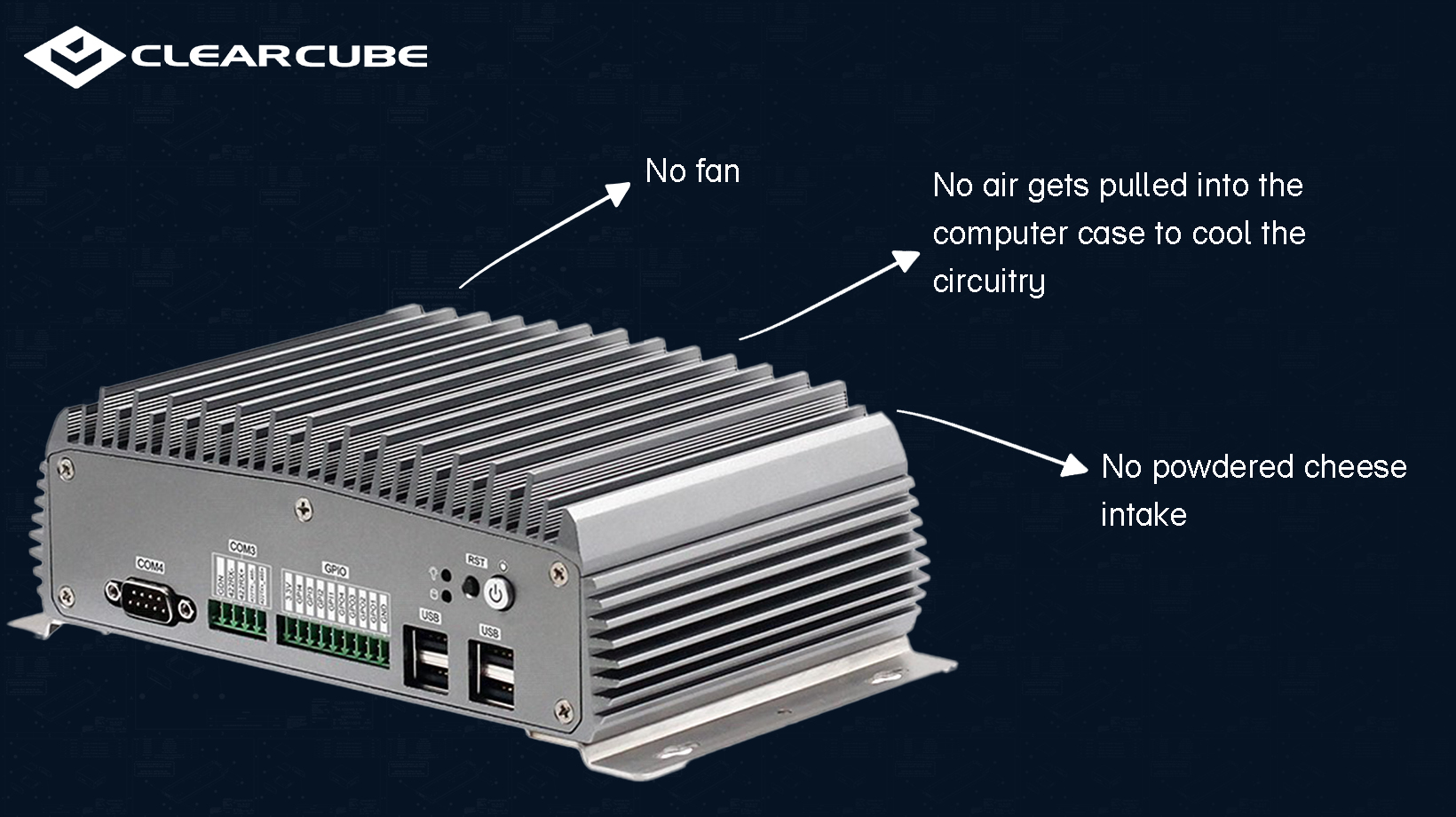

ClearCube Technology provided a low-cost zero client for the production floor. A zero client is the easiest endpoint to manage. It’s a sandwich-sized device with no moving parts, no local data storage, no user-accessible memory, and no OS. If desired, unused I/O ports can be covered. In this example, the zero client was connected to a powerful ClearCube blade PC safely kept in the server room, far from any powdered cheese. This setup met the specific needs and preferences for computing power and ultra-low-maintenance hardware on the factory floor. No fan means no air gets pulled into the computer case to cool the circuitry. No air intake means no powdered cheese intake. This eliminated much of the repeated maintenance, repair, and replacement of the traditional PCs, saving IT time for other projects and priorities. Moreover, the IT team could maintain and service the blade computer from the server room, saving precious time and money.

All kinds of substances common to manufacturing settings can be detrimental to computer performance and lifespan. Fumes, and off-gassing of materials can cause corrosion of computer components. A fan that pulls in thousands of cubic feet of air across those sensitive components accelerates the damaging effects. Consider the environments in these types of operations:

- Rubber

- Cement

- Paint

- Chemical and petrochemical

- Food and household products

- Plastics and building materials

- Steel and metals

It’s not just the intake of air into a PC that can be problematic. Fan-less computers are important in sensitive work areas where air circulation from a computer fan can be detrimental.

Fan-less PCs that employ passive cooling and sealed components are another terrific option in these kinds of environments.

Sometimes it’s not the air that’s harmful to the computer, but it’s the computer-caused air disturbance that can create problems within some work environments. Research laboratories often need to avoid air circulation that could spread mold spores or disease-causing microorganisms. In a lab studying communicable diseases, spreading contaminants via air disturbance could jeopardize the research and potentially create health hazards.

Fan noise can be an issue in certain environments. Newer fan types are available, allowing for near-silent fan operation in a PC that’s not running a high-powered processor or GPU, but mass-produced desktop computers still come with cheaper, noisier fans. A fan-less PC is silent.

Another important attribute can be a computer’s ability to operate in high-temperature environments. Enclosed spaces, such as inside digital signage or kiosks, could be very hot and have poor air circulation. Some industrial settings are exceptionally hot, and it’s important to utilize a computer built to withstand higher temperatures is required for reliable operation.

Some fan-less computers come with an IP rating that indicates the degree to which they are impervious to particulates. There are different degrees of IP ratings, and it’s important to match the device’s IP rating to the environmental requirements.

ClearCube Technology offers a line of fan-less computers and computing devices to meet a variety of requirements. If you need a PC with an IP-50 rating, we have it here. We also have units that provide reliable performance in high-temperature situations. ClearCube also has zero clients and thin clients that can connect to our rack-mounted PCs and blades.

Our friendly, competent team is ready to talk to you about your needs and to help you understand the best products for your situation (without selling you things you don’t need). Give us a call today and check out our industrial-ready products here.